Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Screw Blowers

How can we help you?

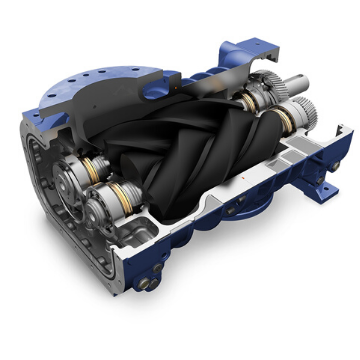

The Robuschi oil-free screw blower airend is a positive displacement machine with rotary motion, also known as “helical screw” compressor.

It delivers constant flow (volume) and variable pressure, which means that at a given speed (rpm), the compressor airend always supply the same amount of air, independently by the pressure variation.

The screw blower airend consists of a pair of helical profile rotors (one male rotor with 3 convex lobes and one female rotor with 5 concave lobes or “flutes”), contained in a casing.

The rotors turn in opposite direction maintaining precise alignment by means of timing; meshing they form a series of working chambers between the rotors and the casing wall.

The gas is sucked from the intake side (suction), trapped between the rotors and the casing (radially) and the cover (axially), transported to the compression side (discharge) where the working chamber shrinks, and compressed. The internal compression leads to supply a steady, non-pulsating air flow, minimizing vibration and maintenance and maximizing lifetime.

Due to the fact that there is no oil for sealing (oil-free screw), the rotors have very precise and small tolerances to maintain a very small air-gap between the two in order to guarantee optimal performance without touching each other.

We're always researching and developing new equipment and technical features to create custom solutions that meet your specific needs. If you require different colors, seals or additional instruments, feel free to contact us !

Do you need engineered solutions?

Visit our page about ETO SOLUTIONS.

The Robuschi screw blower range combines innovative components, cutting-edge design and outstanding efficiency. The result is a very comprehensive choice of screw blowers that includes Robox Screw and Robox Energy series.

The new Robox Screw blower fits the state-of-the-art CDL airend. This patented screw blower is equipped with 3x5 profile rotors designed with wide diameter shafts. This reduces the deformation caused by internal and external loads, and ensures the blower can work efficiently in even the harshest conditions.

Thanks to its exclusive design, Robox Screw ensures low noise with a new canopy concept and improved panels. It has a small footprint that uses up to 11% less space while delivering 20% more air flow. It also provides energy efficiency, easy installation and simple accessibility for service and maintenance.

Robox Energy meets the unique characteristics of the RSW "core" (patent) that uses an innovative motor with permanent magnets and an integrated electrical panel. This offers maximum efficiency, compactness, simple maintenance and flexibility for wastewater treatment plant requirements.