Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Multistage Centrifugal Blowers

How can we help you?

Robuschi has a new comprehensive product line of multistage centrifugal blowers broken into small, medium, and large inlet sizes. Our models cover a broad performance range with capacities stretching from 85 to 70,000 m3/h and present their own unique design features and characteristics. With models optimized for 50 Hz markets*, we offer efficient performance backed by our unwavering commitment to innovation. If our blower requires repair to once again reach the level of performance needed for operation, we offer centrifugal blower parts through our networks of approved Robuschi distributors and agents.

Review our portfolio of multistage centrifugal blower solutions below and learn more.

*50 Hz is our standard, but 60 Hz models are also available.

• Small inlet models,

• Medium inlet models,

• Large inlet models,

• 900 Series

• Multistage centrifugal blower package,

• Accessories & spare parts

Multistage centrifugal blowers are rotating machines able to increase the pressure of air or gasses, by means of the centrifugal force normally transmitted by an electric motor.

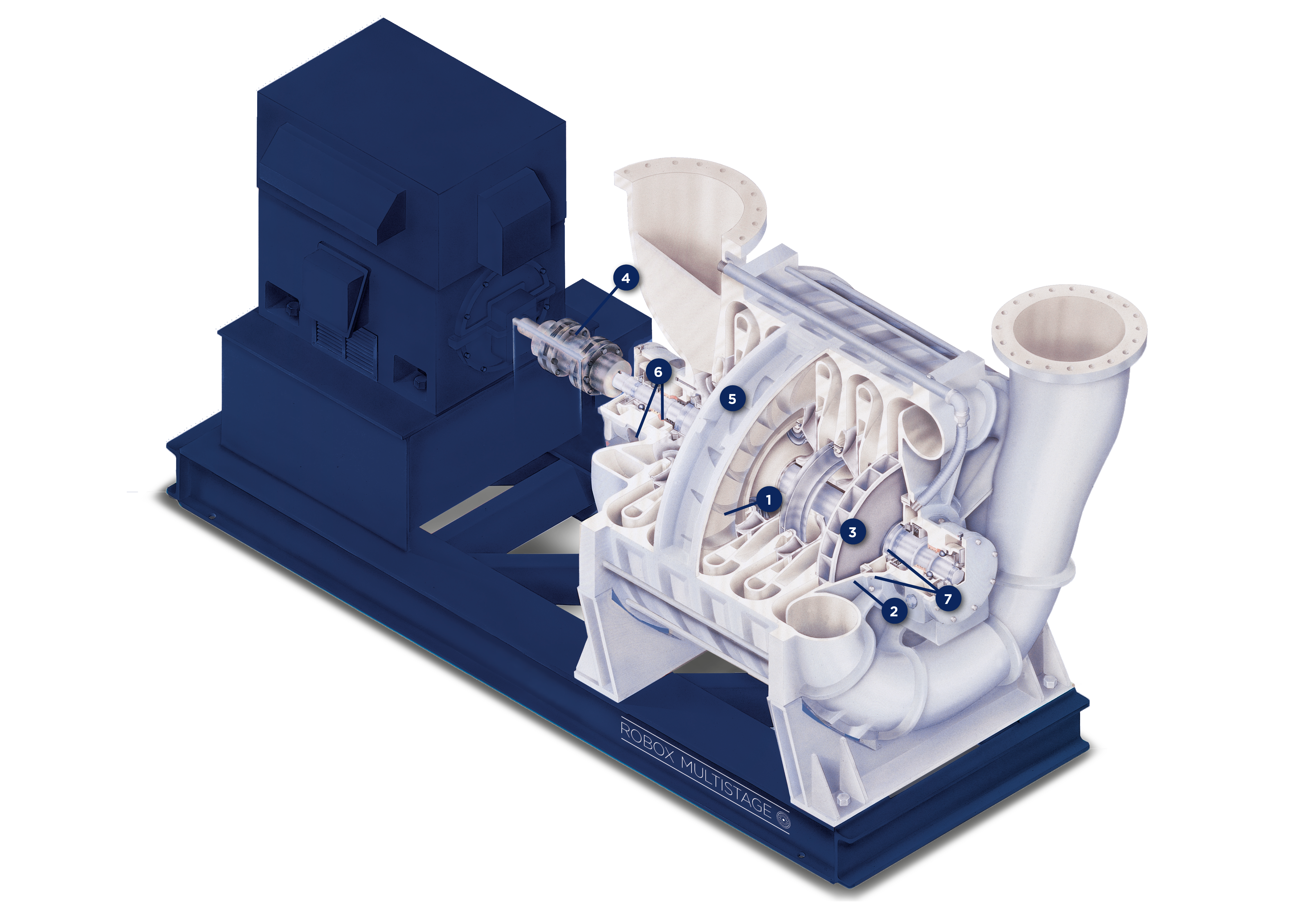

The main components of the Robuschi Multistage Centrifugal Blower product are:

1. Multiple Baffle Rings - Guides airflow smoothly into the eye of the impeller, dramatically reducing inlet passage losses. When combined with the two-dimensional impeller design increases blower efficiency and pressure/vacuum capability.

2. Balance Piston - Negates axial force and reduces pressure on the drive bearings, increases rotor bearing life, and minimizes leakage of compressed gas.

3. Multistage Shrouded Impellers - Two-dimensional shrouded cast aluminum impellers are balanced individually and keyed onto the shaft. On most blowers, the complete assembly is then balanced to achieve smooth operation with the lowest vibration levels in the industry. Rotor assemblies are designed to operate well below the first critical speeds for added reliability.

4. Flexible Coupling - Blowers and exhausters connect directly to the power source with a precision aligned flexible coupling. This optimizes power transfer and minimizes bearing loads for longer life.

5. Cast Housing - Blower housings are precision machined from high-grade cast iron. Smaller models are cast aluminum. The intermediate blower sections are assembled using high strength steel rods. The blower and its driver are mounted together on a single steel baseplate. This assures long-lasting performance and durability.

6. Labyrinth Seal - Minimizes leakage of gas throughout stages and stops airflow from reversing.

7. Carbon Ring Seal/MAXSeal (Mechanical Axial) - For special air and gas applications requiring superior sealing, optional carbon ring seals are available with a purge option.

7A. MAXSeal - An innovation in dry seal technology that reduces fugitive emissions by up to 67% when compared to traditional seal options. Ideal for landfill gas and applications handling toxic and explosive gases. Improves the safety of your operation while extending bearing life and lowering the total cost of ownership.

Equipment is tested prior to reaching the customer or end-user.

This ensures top quality and avoids unforeseeable issues or operational downtime.

Therefore, upholding Robuschi’s strong reputation as the global leader of blower solutions and producing premier quality products efficiently and economically.

Come to discover our Total Blower Capability, one only supplier for a whole range of products.

Robuschi offers a full spectrum of low-pressure technologies, including lobe, screw, turbo and, now multistage centrifugal blowers. You can now benefit from dealing with a single, well-established, knowledgeable supplier for every applications in air, industrial processing, wastewater treatment, and other aeration applications.