Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Industries and Applications

- Wastewater Blowers

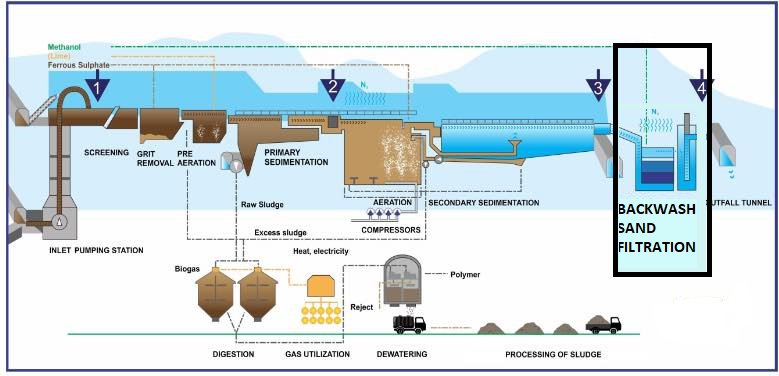

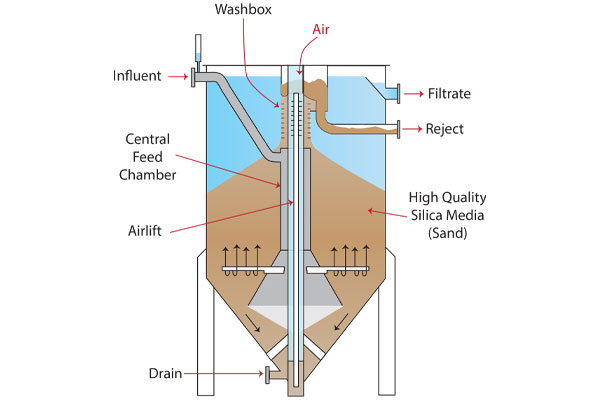

- Backwashing Water Filters | Robuschi