Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

Global (EN)

Global (EN)

- Engineered to Order Blowers and Compressors

- Testimonials

Choose a different country or region to see the content specific to your location

Current Region:

Global (EN)

Global (EN)

How can we help you?

Our constant research and development to ensure customers are able to access new solutions and technical features result in uniquely customized packages which can match any specific requirements, configured to order.

The following cases represent just a few examples of Robuschi’s decades of experience in delivering customer satisfaction.

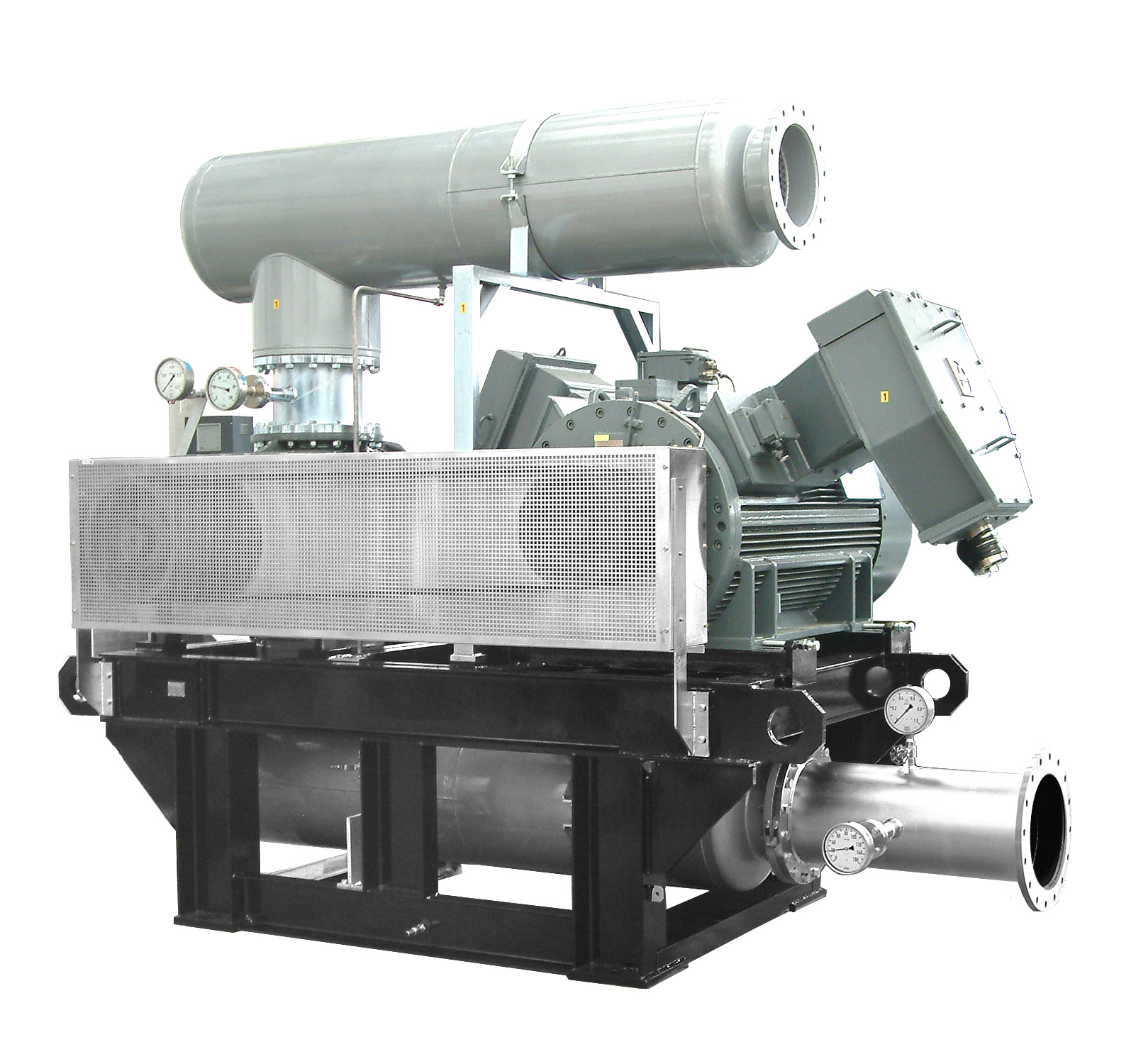

A dry degassing device group in ATEX configuration includes rotary lobe blowers, operating as aspirators to remove the air/methane mixture from mining areas, allowing the mine to operate within the safety threshold. There are 4 sizes of these types of groups, from 3,000 to 8,000 mᶟ / h of aspirated volume operating at vacuum of up to 300 mbar (a).

The groups include two blowers in parallel in order to ensure the reserve in any condition. The suction line includes separator cyclones and filters arranged to remove traces of liquid, powder and solid impurities, which are often present in the mixture from underground mining basins.

Our blower packages are customized and adapted with different kinds of features and accessories to meet your individual needs.Minimize operational costs with easy maintenance and maximize efficiency with the many options available. In support of the system, we are able to add separator cyclones and filters to eliminate powder and solid impurities. We also feature a wide range of ancillary options which result from Robuschi’s long term expertise.

Our accessories are customized according to your technical requirements and vision for a specific product. They are designed for the most extreme conditions to:

System Parameters: 12936 m3/h @ 305 mbar (g)

One of the largest petrochemical sites in India installed 4 customized GRBS 175/V blower units to ensure 24/7 bulk drying purpose as a critical phase of a complex chemical process.The integration of a petrochemical plant into one of the largest crude oil refinery sites in India involved a more complex situation than is typical, which meant that Robuschi’s technical expertise was critical to ensure success. Additionally, extremely high temperatures and humidity, erosion, corrosion, and high pressure drops meant that reliability was an expectation, one which Robuschi were well equipped to match.Polypropylene (PP) is one of the critical side-products realized downstream in crude oil refineries.

In the production of polypropylene, the final quality of bulk material is strictly determined by the drying stage, in which warm pure sutured nitrogen is used to remove humidity from pellets. Accuracy of Robuschi products’ performances represent the perfect fit for this critical quality demand.Benefits at a glance:

A petrochemical company active in Far East Asia, while constructing one of the world’s largest natural gas hubs and extended downstream process plants, required dryer blowers to be fit into sub zero environments in an outdoor installation. With a deep material calculation, selection and test, Robuschi were able to arrange a perfect combination of mechanical and temperature resistance, without any kind of compromise to the end user’s reliability and specification demand.On top of that, our solutions were implemented with the long transit of goods and extreme climate conditions and severe sub zero thermal stresses in mind.

This is additional proof of Robuschi’s capability to serve not only the basic requirements for the PP/PE drying process, but any additional demand. Last but not least, capability to diligently comply with strict local certification, design code and technical regulation added value to our comprehensive project management service to customerBenefits at a glance: