Choose a different country or region to see the content specific to your location

Select Your Country/Region

Current Region:

United Kingdom (EN)

United Kingdom (EN)

- Industries and Applications

- Wastewater Blowers

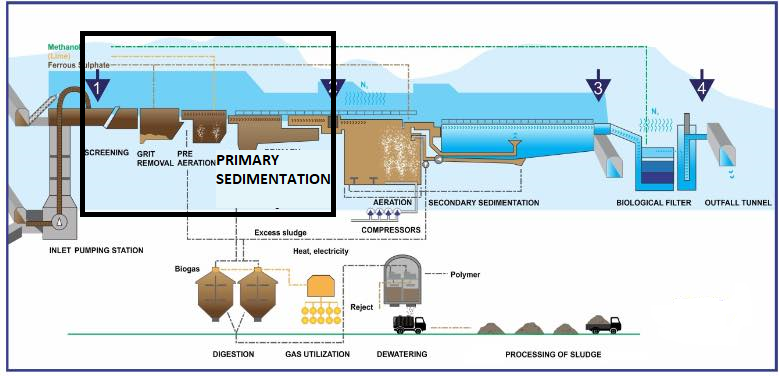

- Primary Sedimentation